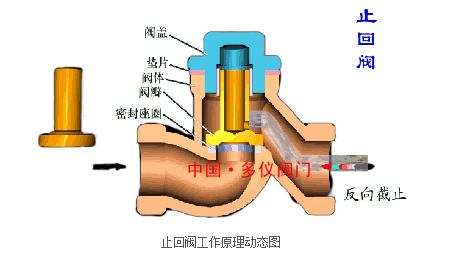

Function and working principle of check valve

The check valve is an automatic opening and closing valve which does not need human or other actions. It depends on the flow of the pipeline itself to open or close the valve, which is mainly used to prevent the backward flow control of the pipeline medium, and Gu is also a check valve or a counterflow valve. The check valve has only one flow direction, that is, only the flow along the inlet can not be reversed, and the valve is closed when the medium is backward. The check valve is usually installed in the area where the valve is not closed when the medium is reflued. Like the outlet of common pumps, check valves will be installed to prevent high-pressure water from flowing into the pump, causing pump impeller or other components to loose or damage due to hydraulic impact, resulting in accidents. In short, check valves are used in pipes and equipment to prevent reflux.

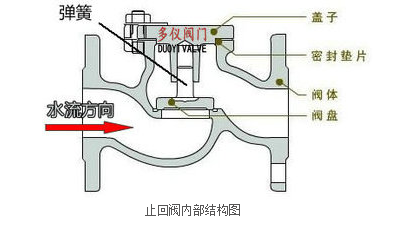

The principle of the check valve is very simple. As shown in the picture, the medium flows in a specified direction. When the flow pressure exceeds the opening pressure of the check valve, the disc is opened under the action of the fluid pressure, thus connecting the circulation of the pipe medium. Conversely, when the pipeline media backflows, the valve is pressed on the check valve body under the push of the fluid pressure, and the valve is closed, thus cutting off the pipeline medium circulation. And the greater the pressure of the reflux medium, the tighter the valve's valve closes, the better the sealing effect is, and the possibility of the reflux of the medium is completely eliminated.